Product Description

Madness is a lightweight ‘Pacific’ or windward proa, intended for fast cruising with two adults or day-sailing with four. With a payload of just under 1000 lb (450 kg), accommodation is ideal for an adventurous couple who want to cover a lot of ground and is ideal for island-hopping.

The design brief was for an elegant, inexpensive, and relatively easy-to-build multihull for fast cruising. Much care was taken to avoid exotic, difficult-to-use materials like carbon fibre and the hope is that this design is more accessible to the home builder than anything capable of the same speeds.

Madness was inspired by, and designed in direct consultation with, proa guru Russell Brown. The design is a fusion of his 30-foot plywood Jzero design from the 1970's, his more-refined cold moulded 36-footer Jzerro, from 1993, and John Harris' own experiences with the proa Mbuli, which he designed and built in 2000.

The Proa Rationale

In the Western Hemisphere proas are still considered somewhat experimental, notwithstanding the pronounced success of westernised proas by Dick Newick and Russell Brown, which have accumulated tens of thousands of sea miles. As so few western sailors have experienced a Pacific proa (in which the outrigger is kept to windward), much is made of their tacking procedure: the boat is stopped, the boom swung around, and one bow is exchanged for another. On paper, this is a head-scratcher.

On the water, however, even a sailor with moderate experience ‘gets it’ instantly and falls under the spell of the proa's peculiar handling advantages. Tacking a proa, a cause of confusion and concern among armchair sailors, is revealed on the water to be a casual exercise undertaken without the slightest drama, no matter the conditions. In a conventional western sloop of similar horsepower and performance, tacking is a frantic exercise of flogging and fouling jibs, dangerous swinging booms, the danger of hanging up in irons, and a delicate process of gathering way again on the new tack as quickly as possible. Jibes are worse.

In a proa, the boat is stopped in tacking and jibing and holds station on its own with the mainsail feathered to leeward. (It's a good time to take a moment and grab a beer, something that would be unthinkable in a conventional boat mid-tack.) One jib is dropped and another hoisted on the new tack. When ready, you throttle-up with the mainsheet and presently you're doing 15 knots on the new tack. The process isn't ideal for short-tacking up narrow channels. However, Madness has been proportioned to handle well on all points under mainsail alone.

Proas are the only sailboats that can be reliably stopped, parked, and reversed on whim. John Harris has never been in any sailboat type that he'd rather work into a crowded harbour under sail on a windy day.

Having got the handling peculiarities out of the way, everything else about the proa configuration is absolutely compelling. Few multihulls can boast a lighter or easier-to-engineer structure. This pays off for the home-builder, who is spared the need for high-modulus crossbeams and attachments. There is simply less to build than either a trimaran or a catamaran.

Proa sailors enjoy other handling advantages. Instantly noticeable under way is the easy motion. With the outrigger just skimming the water (unlike the trimaran's hard-pressed leeward ama), the lack of nervous pitching is easy on the crew and keeps airflow attached to the sails. And the unusual rig geometry of the Brown-styled proa sloop opens a huge slot between jib and mainsail, making this style of proa exceptionally close-winded.

Main Hull:

- LOA: 30′8″

- LWL: 29′3″

- Beam: 28½″

- Beam, overall: 8′3″

- Displacement: 1989 lb

- Moment to Trim One Inch: 274 lb

- cP: 0.60

Ama:

- LOA: 22′5″

- Beam: 21½″

- Displacement, normal sailing lines: 387 lb

- Displacement, immersed to deck: 2029 lb

- Moment to trim One Inch: 79 lb

- cP: 0.60

The complete boat:

- Beam between centres: 14′5″

- Beam overall: 20′0″

- Sail Area: 364 sq ft (Racing) / 294 sq ft (Cruising)

- SA/D: 36.43

- Draft, boards up: 17″

- Draft, boards down: 42-1/2″

Construction

Madness is built using techniques that are state-of-the-art for about 1975. 6 mm okoume plywood panels are stitched-and-glued together very quickly and sheathed on both sides with 6-ounce glass fabric. Every part in the boat is pre-fabricated on the bench.

Even without resorting to exotic materials, a very light hull is the result. The stripped main hull of the prototype is 500 pounds (227 kg). The outrigger, crossbeams, rig, and outboard account for another 500 pounds, thus, at 1000 lb (450 kg) rigged, Madness compares directly with a Farrier F-24 in terms of SA/D – at a tiny fraction of the cost and building complexity.

Accommodation

Something is gained, and something is lost: proas don't have a lot of volume for their length. However, the payload is just under 1000 lb, which will allow two uninhibited adults to cruise for months, or three to race the boat for a few days.

There are two berth flats fore and aft in the main hull, plus a wide, comfortable berth in the lee ‘pod’. On Madness, one of the berth flats has been converted to conceal a chemical head, and above it is mounted a lightweight galley that slides out of the way.

In good weather the crew will sometimes sleep on the trampoline.

The ama contains self-draining lockers for lines and fenders.

Handling

The skipper drives the boat from the motorcycle-sidecar-like cockpit adjacent to the cuddy. Draglinks are led from the tiller yokes to the cockpit. The crew occupies a comfortable park bench style seat on the trampoline to windward of the outboard sled.

The lee pod makes capsize very difficult. In four proas featuring a lee pod of similar proportions, Russell Brown has accumulated ocean crossings and 30 years of coastal sailing without managing anything more than a few knock-downs. Additionally, the outrigger contains up to 700 pounds (320 kg) of water ballast. The ballast tank is filled using very simple and reliable plumbing: a bucket through a deck plate. It's emptied with a bilge bump.

The mast is stepped on the windward edge of the cockpit, with all halyards right at hand. Winches and sheet cleats are located on the flange that stiffens the mast bulkhead. Because the mast is mounted 39″ to windward of the main hull's centreline, struts are required to sheet the mainsail.

The jibs are mounted on continuous-line furlers. In tacking, the current jib is rolled up, then doused completely to allow the boom to swing 180 degrees onto the new tack. Then the ‘new’ jib is hoisted and unfurled. The mast may be rotated through about 90 degrees for best performance.

Because of the mast location, there is no danger of losing the mast in an aback situation because it is supported by stays to the four corners of the boat. The very broad staying base allows a lighter mast, with spiralling gains in weight and complexity.

Provision is made for an asymmetrical spinnaker.

Madness is being fitted with the square-top rig shown in the drawings. A smaller cruising rig is meant to inspire builders to look for used masts and sails, which will cut the costs dramatically. Madness's carbon stick and Vectran sails cost as much as the entire hull.

An outboard of 2 to 6 horsepower is mounted on a retractable sled beneath the crossbeams, convenient to the skipper.

Transport

Madness is completely demountable for road transport. Six easily accessible bolts in the main hull and four bolts on the outrigger fasten the crossbeams, and two pins disconnect the outboard sled. With the main hull at 500 lb (227 kg), a group of friends can lift it onto a trailer. It measures 8′3″ at the widest point, making towing relatively easy behind a medium sized vehicle. Total trailer weight is comparable a Leisure 17 trailer sailer.

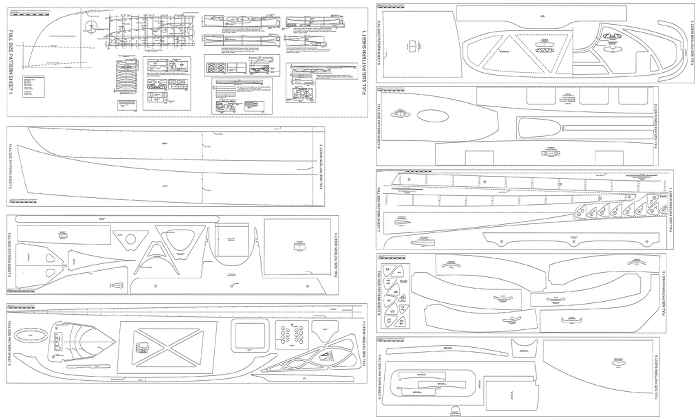

Plywood and Templates

This includes all of the boat's plywood components (35 sheets' worth), CNC-cut and packed on a pallet, plus CNC-cut templates for solid wood components like rudders. The necessary architectural drawings are included.

Solid Wood

This contains the solid timber required for stringers, cleats, rudders and the strip-planked cabin top and akas. The Paulownia strips are milled with bead-and-cove joints for quick assembly.

Hand selected spar-quality Douglas Fir is used for lightly loaded stringers and Sitka Spruce is included for stressed components including rudders. Some of the parts will be pre-cut to the finished dimensions, but you will still need a table saw for shaping the wood.

Epoxy Package

The epoxy package for Madness includes the epoxy resin and fillers needed to build the boat. Three types of epoxy fillers are included: wood flour blend, microfibres and glass fairing balloons. Some of the epoxy comes in large bottles with measuring pumps for dispensing the correct ratio of epoxy and hardener. The rest of the epoxy comes in drums, with drum taps included for refilling the bottles.

Sheathing Package

The sheathing package will take care of 95% of the structural sheathing and bonding requirements during construction. It includes:

- Glass fabric in various weights for sheathing

- Unidirectional and biaxial glass tapes for structural reinforcement

- Carbon fibre for high-stress zones

- Peel-ply for a professional finish

Complete Plans

The complete Madness Proa plans include 31 sheets of architectural drawings covering all construction details, including both racing and cruising rigs. Also included are full-size templates for nearly every part in the boat, on over 100 linear feet of printed paper. An option to build the main hull over a strongback rather than stitch-and-glue-style is included.

Although the plans are copiously detailed, building Madness from plans is not a project for first-timers. Builders should have a solid foundation in wood-epoxy-fibreglass composite boatbuilding and fairly sophisticated plans-reading ability. Rigging details are included but familiarity with modern rigging, particularly of the multi-hull variety, is assumed.

All dimensions are in both metric and imperial units. Builders working from the wood kit receive the 31 sheets of architectural drawings but not the full-size templates, which are only needed when building from plans.

PDF complete plans

The full plans for the boat are also available as a PDF download. After credit card authorisation a download link will be sent to the email address put on the order form.

You will need access to a printer/plotter capable of printing a sheet 36″ (914 mm) wide by 165″ (4191 mm) long in order to build the boat using these plans. Please check your print shop is able to print sheets this large before purchasing the PDF plans.

Study Plans

These study plans are intended for pre-build study or to help with the decision to purchase. They include 25 pages of architectural drawings and will help you decide whether or not you can build the boat. It is not possible to build the boat from scratch using these plans alone: you will need the pre-cut wooden panels and forms or the complete plans.

PDF study plans

The study plans for the boat are also available as a PDF download. After credit card authorisation a download link will be sent to the email address put on the order form.